KJ311-4 hydraulic tunneling drilling rig is built for underground mining and tunneling operations requiring multi-station drilling with less time spent. The drilling rig is powered by diesel engine to provide reliable performance ...

This hydraulic tunneling drilling rig is a kind of plateau type drilling rigs especially used for drilling at high altitude. This drilling rig is suitable for drilling hard rock mines with cross sections of 12-35m².

This hydraulic tunneling drilling rig is computer-assisted intelligent tunneling equipment suitable for blast hole drilling in hard rock mining and tunneling with cross sections of 12-35 m².

This hydraulic tunneling drilling rig features a telescopic feed beam, it is suitable for drilling hard rock mines with cross sections of 12-35m². The drilling rig can also realize rock bolting, it is able to drill bolt holes of 2.2m in depth at 4m high tunnels.

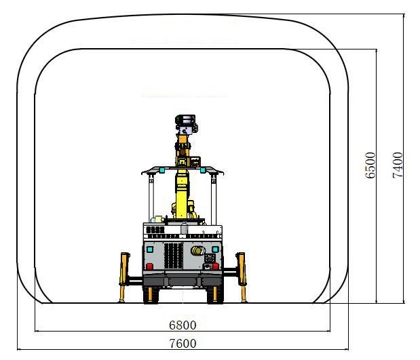

This hydraulic tunneling drilling rig is a face drilling rig designed with increased working height, suitable for large hard rock mines and tunnels with cross sections of 12-44m². The drilling rig can reach a height of 7.4m from floor level, and a width of up to 7.6m.

This two-boom face drilling rig is equipped with two independently controlled drilling systems which enable a higher working efficiency and larger drilling range; It is suitable for drilling vertical, inclined and horizontal holes in hard rock mines and tunnels with cross sections of 12-45m²;

KJ421 hydraulic tunneling drilling rig is a two-boom jumbo designed for drilling vertical, inclined and horizontal blast holes and bolt holes. It is ideal for use in mining and tunneling applications with cross sections from 16m² to 68m².

KJ422 hydraulic tunneling drilling rig is a tunneling jumbo with two booms, designed for drilling vertical, inclined and horizontal blast holes and bolt holes in mining and tunneling projects. This drilling rig is suitable for underground cross sections ranging from 16m² to 95m².

KJ211 hydraulic tunneling drilling rig is primarily used for drilling blast holes in underground mining and tunneling operations. This face drilling rig works independently to drill vertical, inclined and horizontal blast holes, and it is typically suited for hard rock face and cross-cut drilling with cross sections ranging between 7 and 35m².

KJ212 hydraulic tunneling drilling rig is a low profile drill rig able to drill vertical, inclined or horizontal holes. This tunneling jumbo is specially engineered for low-height tunnels with cross sections ranging from 3.5m×1.8m to 5m×4.8m, it can pass through a cross section of up to 2.5m×1.5m.

KJ215 hydraulic tunneling drilling rig is a narrow vein drill rig designed for underground mining and tunneling projects to drill vertical, inclined, and horizontal blast holes. This tunneling jumbo is typically suitable for narrow vein drifts and small tunnels, it has a foldable boom that is perfect for underground hard rock mines and tunnels with cross sections of 5-25m².

KJ310 hydraulic tunneling drilling rig is specially designed for incline tunnel development at a maximum inclination angle of 25 degree. This underground drill rig is an ideal solution for drilling hard rock mines with cross sections of 12-35m².

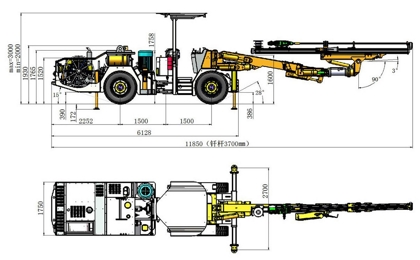

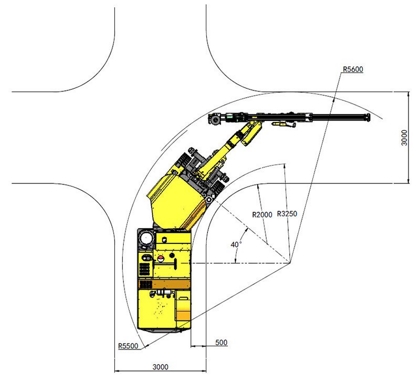

KJ311 hydraulic tunneling drilling rig is a secondary breaking drill rig engineered for hard-rock mining and tunneling operations, with cross sections of 12-35m².